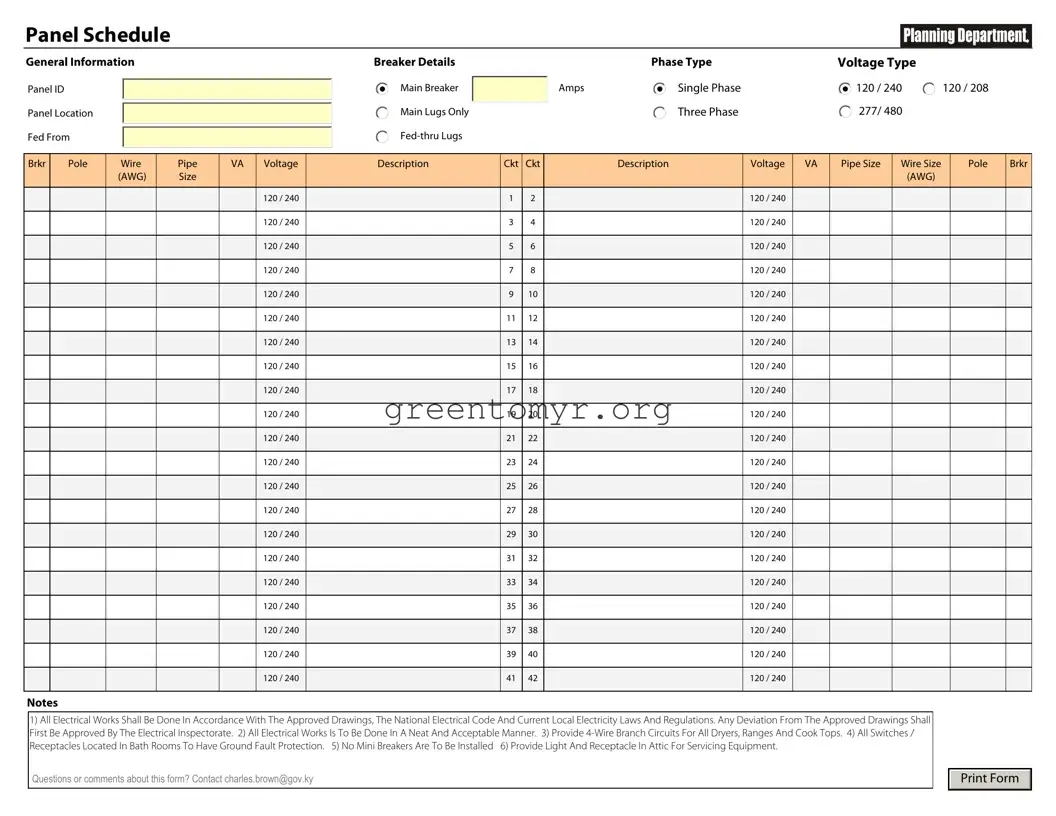

Filling out the Electrical Panel Schedule form is a critical step in managing electrical systems correctly. However, many people make common mistakes that could lead to serious issues down the line. Understanding these missteps can help ensure that your submission is accurate and meets all requirements.

One frequent error is neglecting to provide the correct identification for each circuit. Each circuit should be labeled clearly and concisely. Without accurate labels, it becomes challenging to identify the circuits during maintenance or in emergencies. This can lead to dangerous situations where the wrong circuits are accessed.

Another mistake is failing to include load calculations for each circuit. These calculations are essential for determining whether the electrical panel can handle the demands of the connected circuits. If omitted, it could result in overloading the panel, leading to potential safety hazards and costly damages.

Some individuals also forget to update the schedule after making changes to the system. As new circuits are added or existing circuits are removed or reconfigured, the schedule must reflect those changes. Keeping the form up-to-date is vital for ongoing safety and compliance.

Furthermore, people often overlook ensuring compliance with local codes. Each jurisdiction has specific electrical codes that must be followed. Failing to align the Electrical Panel Schedule with these regulations can lead to significant legal and financial repercussions.

Additionally, incorrect voltage or amperage ratings is a common error. Every circuit should report its specific voltage and amperage clearly. Misstated ratings can mislead technicians, resulting in wrongful connections and serious operational failures.

It is also essential to carefully double-check spelling and formatting. Sloppy presentation or typos can lead to misunderstandings during inspections or maintenance. A clear and professionally presented document reflects attention to detail and enhances communication.

Finally, some individuals fail to sign and date the form appropriately. Missing signatures can render the schedule invalid, delaying necessary inspections or approvals. Always ensure that the form is fully completed with all required validations to avoid unnecessary complications.

By recognizing these common mistakes and taking proactive steps to avoid them, you can significantly improve the accuracy and effectiveness of your Electrical Panel Schedule. Properly managed schedules not only enhance safety but also facilitate seamless operations in your electrical system.