What is a Pre Trip Inspection Checklist?

The Pre Trip Inspection Checklist is a tool used by drivers to systematically assess the condition of a vehicle before it is put on the road. This checklist helps ensure safety and compliance with regulations by prompting drivers to check critical components of the vehicle.

Why is a Pre Trip Inspection important?

A Pre Trip Inspection is vital for maintaining safety on the road. By checking the vehicle before departure, drivers can identify potential issues that could lead to accidents or breakdowns. This proactive approach can prevent costly repairs and ensure compliance with safety regulations.

Who is responsible for completing the checklist?

The driver is primarily responsible for completing the Pre Trip Inspection Checklist. However, fleet managers and safety officers should also encourage the practice, as it enhances overall road safety and accountability.

What items should be included in the checklist?

A comprehensive checklist often includes, but is not limited to:

-

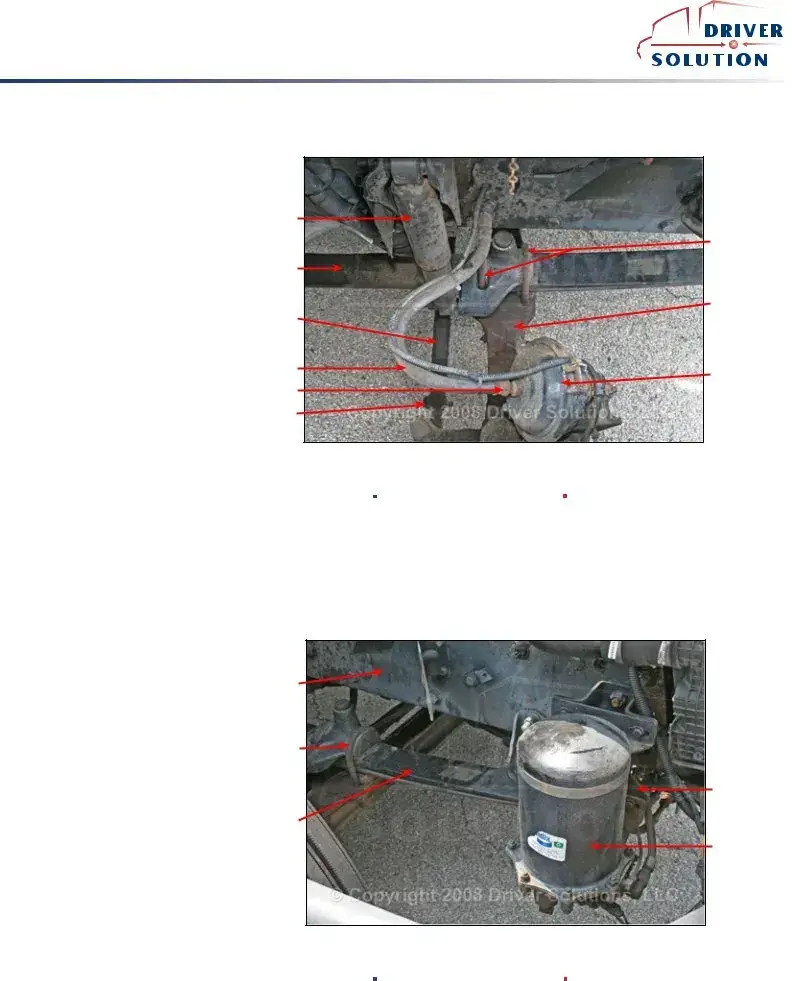

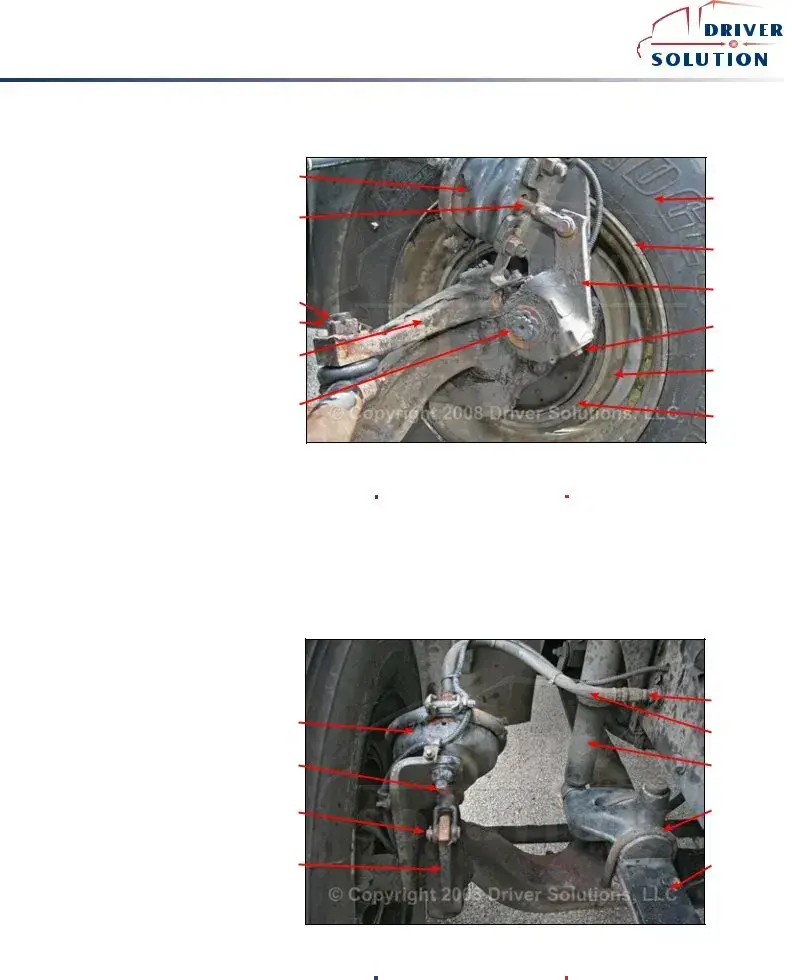

Brakes

-

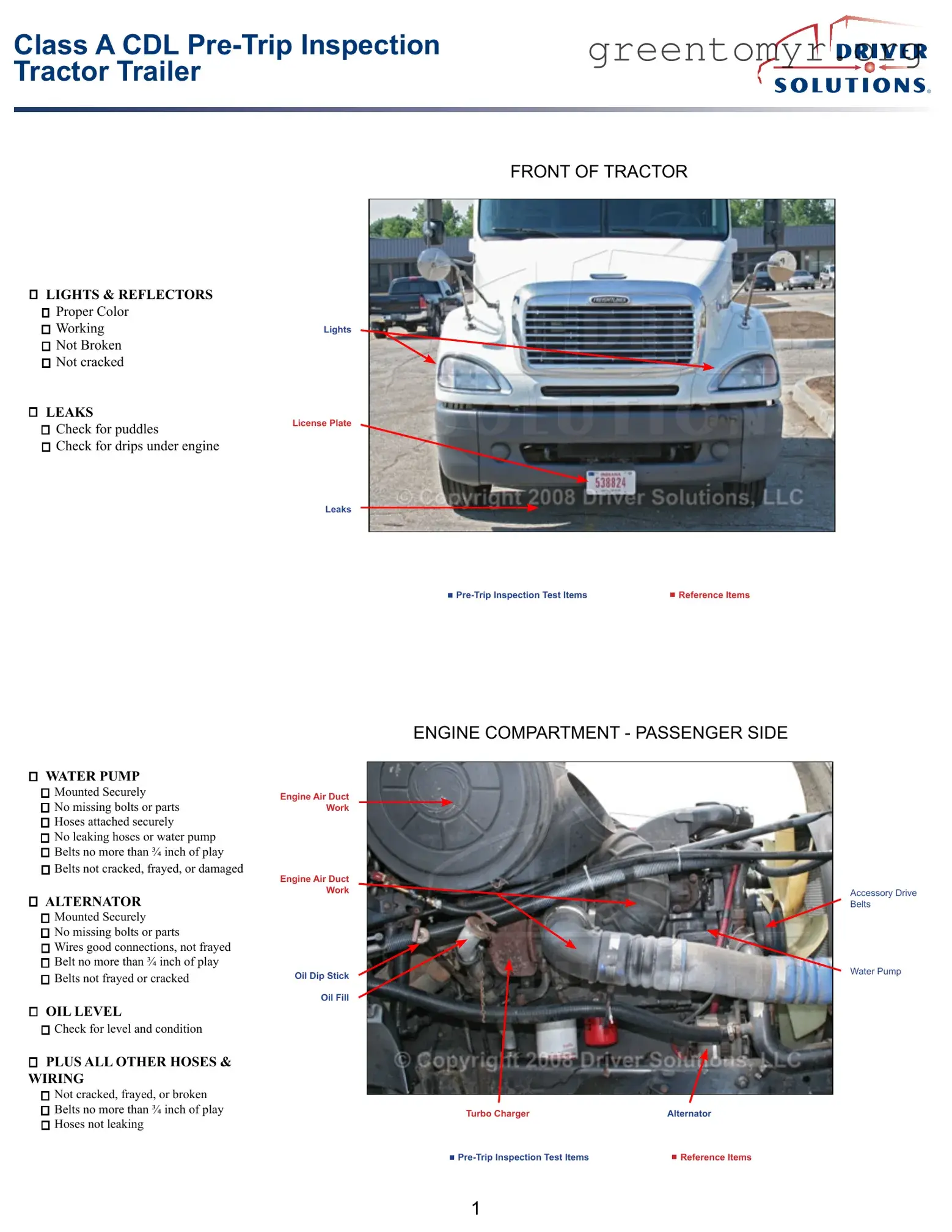

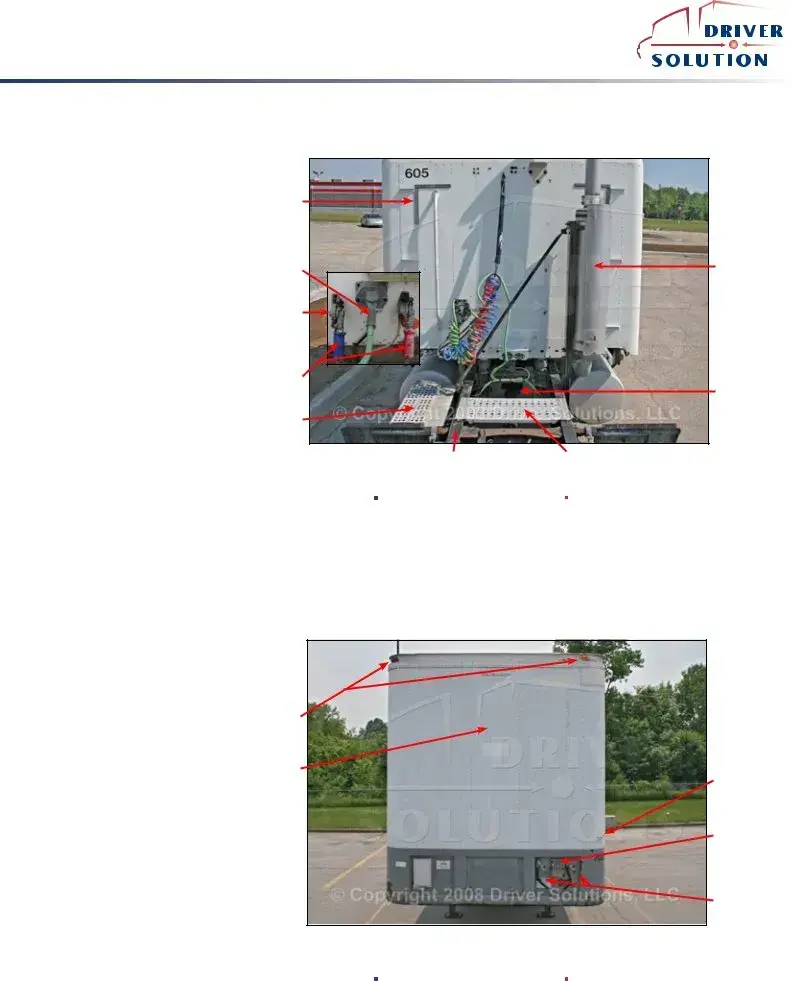

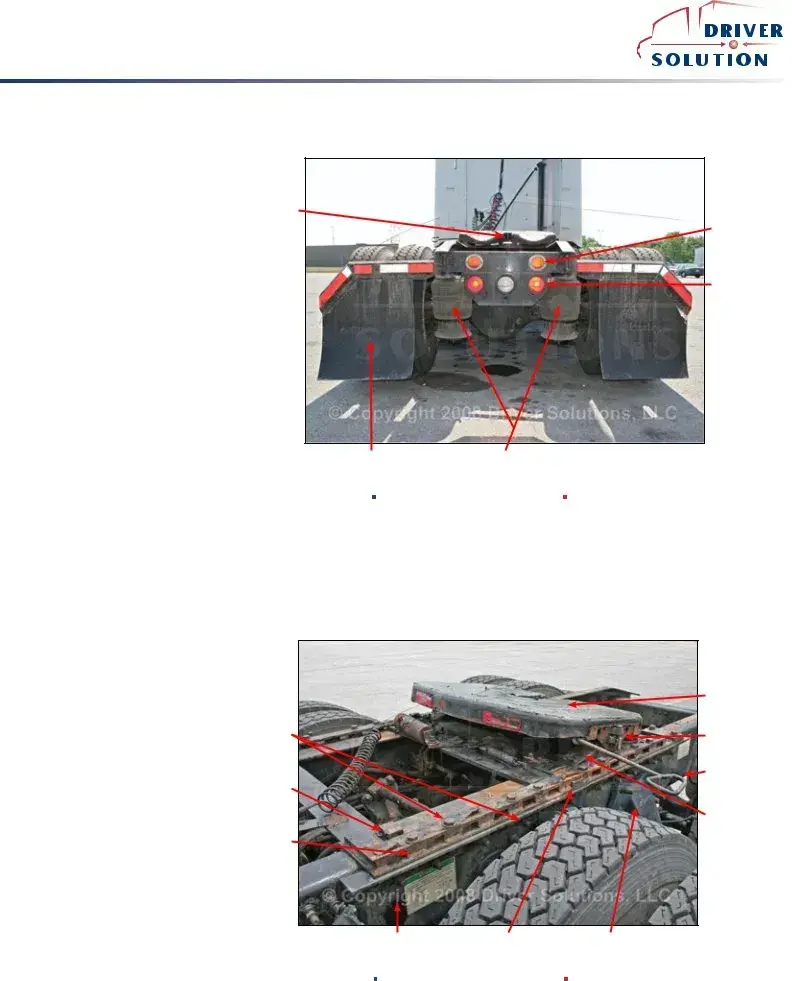

Lights and Reflectors

-

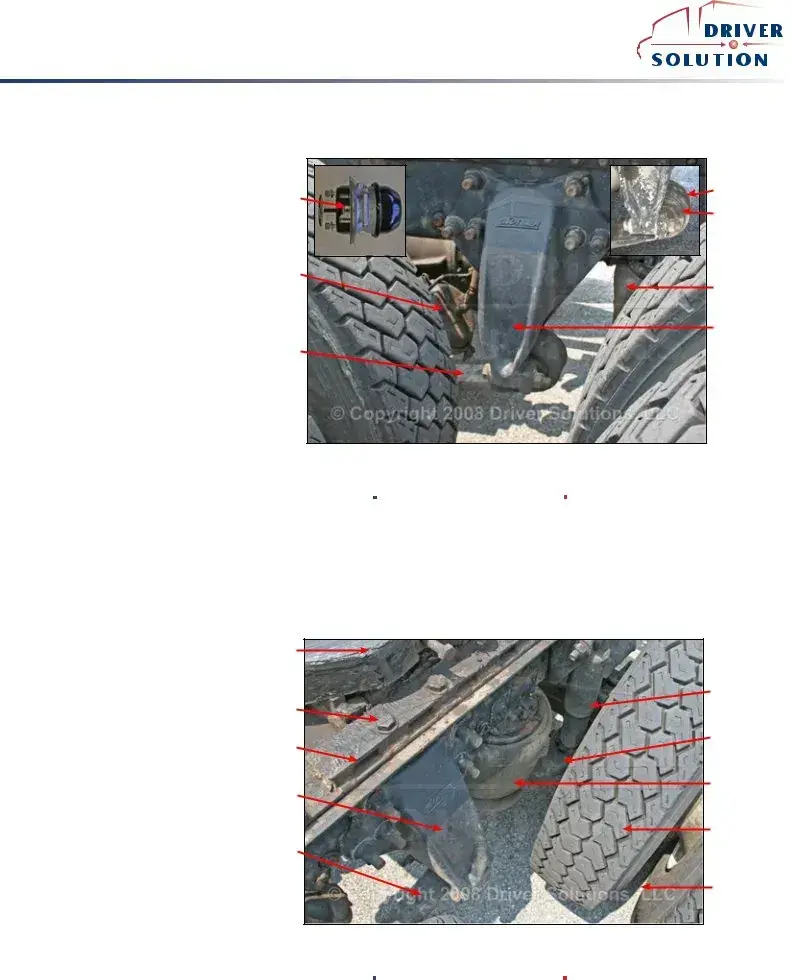

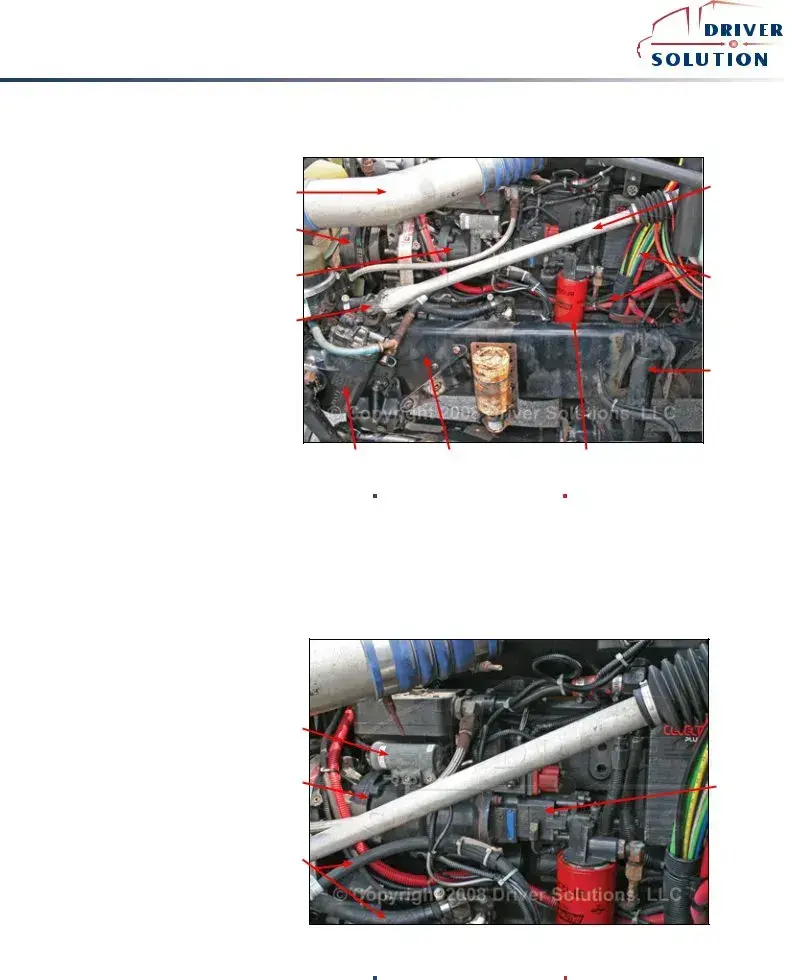

Fluid Levels (oil, coolant, etc.)

-

Tires (pressure and tread depth)

-

Windshield Wipers and Washers

-

Safety Equipment (fire extinguisher, triangles)

Each of these components is crucial for the vehicle's operation and safety.

How often should the Pre Trip Inspection be conducted?

The Pre Trip Inspection should be conducted every time a driver prepares to operate a vehicle. Consistency is key for ensuring the vehicle remains in good working condition and is safe for the road.

What happens if an issue is found during the inspection?

If a driver identifies an issue during the inspection, it should be reported immediately. Depending on the severity, the vehicle may need to be repaired before it can be safely operated. Documenting the issue is also recommended for record-keeping and compliance.

While the checklist can vary from one organization to another, it must contain a clear layout that outlines all the necessary inspection points. Many companies develop their own formats, but it should always be user-friendly and comprehensive.

Can the checklist be digital or does it have to be paper-based?

The checklist can be in either a digital or paper format, depending on the preferences of the organization and the resources available. Both formats can be effective as long as they are easily accessible and properly maintained.

What are the consequences of not conducting a Pre Trip Inspection?

Failing to conduct a Pre Trip Inspection can lead to serious safety risks, mechanical failures, and potential legal repercussions. Accidents caused by neglected vehicle maintenance may result in liability issues, fines, and increased insurance rates.

How can drivers be trained to conduct effective inspections?

Training drivers to conduct effective inspections can include hands-on demonstrations, providing written materials or checklists, and allowing experienced drivers to mentor newer ones. Regular training sessions help reinforce the importance of inspections and keep safety top of mind.

®

®

®

®

®

®

®

®

®

®

®

®

®

®

®

®

®

®

®

®